PART I: FINDING FRAC SAND

In the oil and gas industry we hear lots of people talk about the shale revolution. Oil companies knew about oil trapped in tight shale formations for years before they developed strategies to get that oil out—strategies that involve pumping huge amounts of water and sand into the formations to “prop” them open to allow the oil out.

That’s why we call our sand a “proppant.”

Ten years ago it was thought that the only sand that would prop things open came from Wisconsin and Illinois—called “Northern White.”

But it costs a lot of money to ship that sand across country—hundreds of thousands of dollars per well.

In the last couple of years the industry has learned that they can use nearby sand in the Permian Basin, the Eagle Ford and in Oklahoma, saving a large chunk of that money.

So how do we locate the billions of tons of sand supplies we need in a basin and how do we get permission to truck it out? It’s a surprisingly complex process.

Finding the “Sweet Spot”

We start by studying geological maps to find sand of the quality and quantity we need, in proximity to drilling activity.

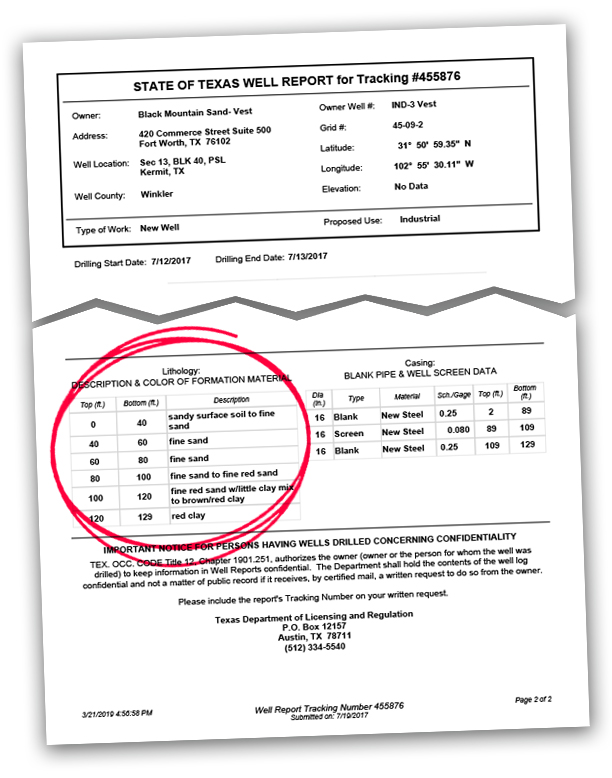

Once we’ve mapped the geology deposits, we study logs from previously drilled water wells. By seeing what layers the drillers were cutting through, we start to learn the depths of the sand deposits.

Some logs from other west Texas regions have revealed layers of sand, caliche, water and various types of rock. Most areas showed a majority of sand.

We also begin proving sand depths and types of sand in the area. In that, we’re determining the availability of the variety of mesh sizes our customers need. We drilled about 600 core holes through Ward and Winkler counties to more finely hone our information.

But sand isn’t all we need. To collect the sand, sort it by mesh size and get it on the road to operators and completions companies we require huge supplies of water, natural gas and electricity.

We’re also keenly aware of our environmental responsibilities. Habitats for local species like the dunes sagebrush lizard are on our minds as well as how our operations affect the land. We’re dedicated to being good neighbors.

Acquisition

After defining the “sweet spot” that combines the right sand with access to roads for trucking and utilities, we go into acquisition mode. Our greatest hope is to find that large areas are owned by one entity. That means we only have to talk to one or two people instead of several dozen.

We’ve been asked why there are so many sand mines in one area—we ourselves have three in the Permian Basin and single mines in other areas as of 2019.

The short answer is, since we discovered local sand works well in fracing operations, we needed to be local. Since a large part of the cost of obtaining frac sand lies in the logistics, the closer we are to our clients, the more money we save them.

We are not alone. Everyone is aware of the same economics we are, and since most sand mines are compact, acreage-wise, several mines can operate in close proximity.

It’s just like Detroit. The car makers are there, so that’s where you’ll find makers of windshield wipers, lug nuts, windshields and everything that goes into a car.

If you’re interested in a more in-depth look at fracturing and frac sand, here’s a link: https://www.blackmountainsand.com/resources/what-is-frac-sand/

Next Time:

Now that we’ve located sand and opened for business, what’s that like? How does a “day in the life” of a frac sand mine play out? Next month, we’ll talk to a plant manager to get the grit.

We Want To Hear From You!

Have questions? Comments? We’d love to hear from you! We want to get to know our neighbors, so please send us your questions on the form below. We’ll share your questions with our answers on social media each week! Follow our story: #InsideFracSand

This Month’s Contributor

Brittany Schamaun

GIS Coordinator

As GIS Coordinator at Black Mountain Sand, Brittany captures and displays data and maps specific to Black Mountain Sand’s needs. She organizes our geological surveying projects and helps identify new land developments and enhancements. Native to New Braunfels, Texas, Brittany is a graduate of Texas State University where she earned a Bachelor of Science (B.S.) in Geographic Information Systems.